Introducción - Importancia de las ventanas de inspección en los sistemas de monitorización

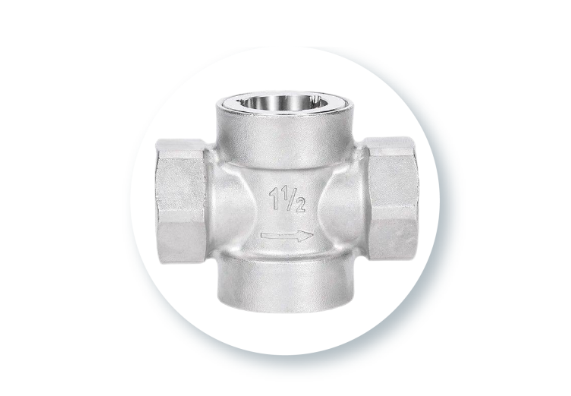

Los visores desempeñan un papel clave en la supervisión de sistemas en numerosas industrias. Estos permiten a los operadores observar directamente lo que ocurre en el interior con los fluidos: la cantidad existente, si se ven limpios o turbios, y si el flujo es el adecuado en ese momento. Cuando algo comienza a fallar en un sistema, estos visores de vidrio permiten detectar rápidamente los problemas antes de que se conviertan en asuntos mayores que puedan causar averías en equipos costosos y generar gastos innecesarios. La posibilidad de ver directamente dentro de tanques de almacenamiento, a través de tuberías y diversos recipientes, facilita enormemente la toma de decisiones en el lugar de trabajo y contribuye a mantener la seguridad de todos los que operan cerca de materiales potencialmente peligrosos. Para los responsables de plantas que manejan maquinaria compleja día a día, los visores ya no son solamente elementos para inspeccionar visualmente; se han convertido en componentes esenciales de las rutinas de mantenimiento regulares que garantizan un funcionamiento continuo y sin interrupciones imprevistas.

Funcionamiento fundamental de las ventanas de inspección

Los visores desempeñan un papel fundamental en diversos sistemas de monitoreo, ya que permiten a los operadores verificar los niveles de fluidos, observar la claridad del líquido y examinar las condiciones de flujo cuando sea necesario. Cuando algo parece anormal durante estas inspecciones visuales, los equipos de mantenimiento pueden detectar problemas antes de que se conviertan en asuntos mayores, ahorrando así costos por reparaciones costosas en el futuro. Su diseño transparente permite a los trabajadores mirar directamente dentro de tanques de almacenamiento, a través de secciones de tuberías y en el interior de otros recipientes de contención, facilitando así la identificación de puntos problemáticos y manteniendo las operaciones seguras. Para los gerentes de planta que operan en plantas químicas o instalaciones de tratamiento de agua, este tipo de retroalimentación visual inmediata marca la diferencia para garantizar que las operaciones transcurran sin contratiempos y eviten apagones inesperados causados por fugas o bloqueos no detectados.

Industrias Críticas que Dependenden del Monitoreo Visual

El sector de petróleo y gas, junto con plantas de procesamiento químico y fábricas de producción de alimentos, depende bastante de las ventanas de inspección (sight glasses) para mantener las operaciones funcionando sin contratiempos y de manera segura. Según algunos informes industriales, alrededor de siete de cada diez instalaciones en industrias de alto riesgo utilizan ventanas de inspección como parte habitual de sus rutinas de monitoreo. Estas ventanas de vidrio simples permiten a los trabajadores revisar lo que ocurre en el interior del equipo sin necesidad de abrirlo, lo cual ayuda a cumplir con todas esas normativas complejas impuestas por los organismos reguladores. Por ejemplo, en refinerías donde podría ocurrir una explosión si la presión aumenta demasiado, los operadores pueden detectar problemas desde una etapa temprana solo con mirar a través de una ventana de inspección. Más allá de garantizar que los procesos sean eficientes, estas revisiones visuales desempeñan un papel fundamental en la prevención de accidentes antes de que se conviertan en incidentes mayores.

Identificación Visual de Anomalías e Irregularidades

Los visores desempeñan un papel realmente importante al permitir que las personas realicen inspecciones visuales de forma regular, para que puedan detectar cualquier anomalía en sus sistemas de monitoreo. Los operadores observan a través de estas ventanas de vidrio para identificar signos tempranos de advertencia, como colores extraños, residuos acumulándose en el fondo o flujos que simplemente no parecen normales. Este tipo de observaciones podría indicar problemas de contaminación o cualquier otro fallo dentro del sistema. Cuando los operadores notan estos problemas antes de que empeoren, pueden solucionar lo que esté sucediendo antes de que se convierta en un gran inconveniente en el futuro. El hecho de que los visores proporcionen esta retroalimentación inmediata ayuda a mantener el equipo funcionando de manera eficiente y evita apagones inesperados que conllevan costos de tiempo y dinero.

Estudios de Caso: Prevención de Fallas Catastróficas

Las ventanas de inspección realmente marcan la diferencia a la hora de evitar problemas mayores antes de que ocurran en todo tipo de industrias. Las empresas han obtenido buenos resultados al instalarlas como parte de sus medidas de seguridad. Tome como ejemplo una gran planta petroquímica que logró reducir su tasa de incidentes en aproximadamente un 35 % después de que los trabajadores comenzaran a revisar regularmente los niveles de fluidos a través de estas ventanas de vidrio. La posibilidad de detectar problemas temprano permite que los equipos de mantenimiento intervengan rápidamente y eviten accidentes que podrían llegar a ser graves. Por eso, muchas fábricas consideran actualmente que las ventanas de inspección son equipos esenciales para mantener las operaciones funcionando sin contratiempos ni apagones inesperados.

Integración con Sistemas de Mantenimiento Predictivo

Cuando los visores se combinan con tecnología de mantenimiento predictivo, se convierten en mucho más que simples herramientas de observación. Los datos en tiempo real provenientes de estas ventanas de vidrio fluyen directamente hacia los sistemas de mantenimiento, donde los operadores revisan las condiciones y actúan según sea necesario, basándose en lo que está sucediendo en ese momento. Esto significa una mejor comprensión del estado real del sistema completo. El mantenimiento se vuelve más inteligente y las paradas no planificadas disminuyen considerablemente. Los visores siguen permitiendo a las personas observar visualmente lo que ocurre, pero también desempeñan un papel importante en la planificación de la durabilidad del equipo, al hacer que las estrategias de mantenimiento predictivo funcionen mejor con el tiempo.

Eliminación de los costos por tiempos de inactividad no planificados

Detener fallos inesperados en el equipo ahorra a las empresas una gran cantidad de dinero cada año, y las ventanas de inspección desempeñan un papel bastante importante para lograrlo. Cuando los operadores pueden ver lo que sucede dentro de la maquinaria a través de estas ventanas de vidrio, identifican problemas mucho más rápido que si esperaran a que algo falle completamente. Solucionar los inconvenientes desde el principio reduce los paros de producción y causa menos interrupciones en toda la operación. Las empresas que implementan este tipo de sistema de monitoreo normalmente evitan gastos significativos que afectan directamente a la rentabilidad, los cuales surgen cuando la fabricación se detiene inesperadamente. Algunas fábricas reportan ahorros de cientos de miles de dólares simplemente por detectar pequeños problemas antes de que se conviertan en grandes complicaciones.

Reducción de Costos Laborales mediante Intervenciones Dirigidas

El uso de ventanillas de inspección marca una diferencia real a la hora de reducir los costos laborales, ya que cambia la forma en que se realiza el trabajo de mantenimiento. Cuando estos paneles de vidrio están instalados, los técnicos ya no necesitan revisar todo de una sola vez. En su lugar, pueden mirar directamente a través de ellos para detectar problemas sin necesidad de desmontar componentes primero. El equipo ahorra tiempo, ya que no se pierde esfuerzo en piezas que en realidad se ven bien. Los trabajadores dedican su tiempo a reparar lo que está roto, en lugar de adivinar dónde podrían estar los problemas. Además, este enfoque deja disponible suficiente mano de obra para otras tareas urgentes en la instalación que requieren atención.

Optimización de Recursos mediante la Detección de Fugas/Contaminantes

Los visores de vidrio destacan especialmente a la hora de detectar fugas o cuando contaminantes entran al sistema, lo cual mejora significativamente la gestión de recursos y reduce el desperdicio de materiales. Detectar problemas rápidamente significa que las empresas pierden menos producto y, además, mantienen el cumplimiento de todas aquellas normativas ambientales cuyo incumplimiento puede ocasionar multas elevadas. Estos visores permiten que los equipos de mantenimiento actúen ante problemas antes de que se conviertan en grandes inconvenientes, logrando así operaciones más eficientes y evitando gastos innecesarios en reparaciones mayores en el futuro. Al final del día, las empresas ahorran dinero en términos reales y reducen también su impacto ambiental.

Simplificación de Ajustes en el Control de Procesos

Los visores son realmente importantes a la hora de facilitar el control de procesos, ya que brindan a las personas que trabajan en el lugar información inmediata sobre el desempeño actual de los sistemas. Cuando los operadores tienen este tipo de visibilidad, pueden ajustar rápidamente los parámetros para que las máquinas sigan funcionando sin problemas ni inconvenientes. Las empresas ahorran dinero al reducir el tiempo de inactividad, ya que la producción se mantiene estable la mayor parte del tiempo. Estas ventanas de vidrio permiten a los trabajadores observar el interior de los procesos sin necesidad de detenerlos por completo, algo que mantiene a las fábricas productivas día a día, evitando esas interrupciones costosas que nadie desea. Desde verificar los niveles de líquido en los tanques hasta observar cómo se mueven los materiales a través de tuberías, los visores ofrecen suficiente detalle como para tomar decisiones basadas en condiciones reales, en lugar de conjeturas.

Garantía de Calidad mediante el Monitoreo Continuo

Mantener un control visual mediante ventanillas realmente mejora la calidad del producto, ya que asegura que todo funcione según lo planeado. Estas pequeñas ventanas permiten a los operadores detectar problemas antes de que se vuelvan demasiado grandes, algo que resulta fundamental para mantener los estándares de calidad. Cuando los operadores identifican problemas temprano, pueden solucionarlos antes de que se desperdicien materiales o haya que repetir trabajos más adelante. Las ventanillas de observación desempeñan un papel tan importante en garantizar que los productos cumplan con las especificaciones, que muchas fábricas ni siquiera considerarían operar sin ellas. Básicamente, actúan como la primera línea de defensa contra defectos que de otro modo terminarían en productos terminados, lo que podría costar dinero a las empresas y dañar la confianza del cliente.

Impacto en la Eficiencia General de los Equipos (OEE)

Los visores realmente mejoran la Eficiencia General de los Equipos (OEE), ya que permiten a los operadores ver lo que sucede dentro de los procesos en todo momento. Cuando los trabajadores pueden ver realmente lo que está ocurriendo, detectan problemas temprano y realizan correcciones antes de que las cosas fallen, lo que reduce el desperdicio y mantiene la producción funcionando sin contratiempos. Muchos fabricantes que instalan estas ventanas de vidrio en sus equipos notan mejoras reales en las métricas de OEE, ya que las máquinas funcionan mejor sin detenciones constantes. La conclusión es que los visores ayudan a aprovechar al máximo cada máquina, por lo que las fábricas producen más bienes gastando menos dinero en reparaciones y tiempos muertos. Para los gerentes de planta que vigilan cuidadosamente las cuentas, esto significa márgenes de beneficio más sanos sin sacrificar los estándares de calidad.

Ampliar la vida útil del equipo mediante el cuidado proactivo

La supervisión regular mediante ventanillas de inspección contribuye significativamente a prolongar la vida útil del equipo. Estos paneles de vidrio ofrecen a los trabajadores una visión directa de lo que ocurre en el interior de la maquinaria, permitiendo detectar problemas desde una etapa temprana, antes de que se agraven. Estudios de la industria sugieren que el monitoreo constante de este tipo puede, en algunos casos, duplicar o incluso triplicar la vida operativa del equipo. Esto cobra aún más sentido cuando se considera junto con las técnicas modernas de mantenimiento predictivo, en las que sensores vigilan constantemente los datos de rendimiento. En resumen, la combinación de estas sencillas ventanas de vidrio y sistemas inteligentes de monitoreo permite que las máquinas funcionen durante más tiempo y se ahorre dinero en reparaciones futuras.

Impactos de Sostenibilidad: Reducción de Recursos/Residuos

La incorporación de ventanas de inspección en los sistemas de monitorización ayuda a las empresas a reducir el desperdicio de recursos mientras avanzan hacia operaciones más sostenibles. Cuando los operadores pueden ver realmente lo que ocurre dentro de los sistemas a través de estas ventanas de vidrio, toman mejores decisiones sobre cuándo ajustar la configuración, lo que significa que se utiliza menos energía y materiales de forma innecesaria. ¿El resultado? Menores costos para la empresa y menos impactos negativos en el medio ambiente al mismo tiempo. Muchos fabricantes están descubriendo que simplemente poder observar los niveles de fluidos o los cambios de presión marca una gran diferencia en las operaciones diarias. Los sistemas funcionan con mayor suavidad porque ya no hay que hacer conjeturas, por lo que el desperdicio se minimiza en todos los aspectos. Este tipo de visibilidad directa respalda esfuerzos reales de sostenibilidad sin necesidad de realizar modificaciones mayores a la infraestructura existente.

Estrategias para Mejorar la Conformidad y la Seguridad

Los visores desempeñan un papel realmente importante a la hora de mantener la seguridad y cumplir con las normativas en diversos sectores, desde plantas de fabricación hasta instalaciones de procesamiento químico. Proporcionan a los trabajadores una visión continua de lo que ocurre en el interior de esos sistemas de gestión de fluidos, lo cual ayuda a las empresas a cumplir con todos los estrictos requisitos de seguridad establecidos por agencias gubernamentales y organismos del sector. La presencia de estas ventanas de observación de vidrio fomenta realmente hábitos más seguros en el lugar de trabajo, ya que permite detectar problemas desde el principio, antes de que pequeños inconvenientes se conviertan en accidentes graves que involucren fluidos peligrosos o fallos en el equipo. Para cualquier persona que maneje sustancias potencialmente dañinas, tener acceso visual marca la diferencia para monitorear niveles y controlar los flujos de manera segura durante las operaciones diarias, permaneciendo dentro de los límites legales.

Conclusión - Papel de los Visores en la Confiabilidad y el Mantenimiento del Sistema

La incorporación de ventanas de inspección a los sistemas de gestión de fluidos aporta dos beneficios principales: mejores operaciones y ahorro real de dinero. Estas ventanas de vidrio permiten a los técnicos ver de inmediato lo que ocurre dentro de tuberías y depósitos, por lo que los problemas se solucionan más rápidamente antes de que causen inconvenientes mayores. Esto implica menos averías y un funcionamiento más eficiente del sistema en general. La mayoría de las plantas industriales afirman que su inversión comienza a dar resultados entre 8 y 12 meses después de la instalación. Para los fabricantes que operan con presupuestos ajustados, las ventanas de inspección representan una inversión inteligente que mejora tanto los resultados económicos como las operaciones diarias, en sectores diversos que van desde el procesamiento de alimentos hasta la fabricación química.

Innovaciones Futuras en Tecnología de Monitoreo Visual

El futuro parece prometedor para la tecnología de ventanas de inspección, ya que estamos viendo desarrollos bastante emocionantes en el horizonte. Estamos hablando de la integración de sensores avanzados directamente en estas ventanas de visualización, lo que significa que los operadores obtienen datos mucho más precisos sobre lo que sucede dentro de esos recipientes. A medida que la tecnología de sensores sigue mejorando, la monitorización visual a través de las ventanas de inspección se vuelve más precisa y confiable que nunca. Esto no es solo teoría: las plantas ya están experimentando mejoras medibles en sus operaciones gracias a estas actualizaciones. Para los equipos de mantenimiento en particular, tener acceso a este tipo de información detallada facilita enormemente la detección y resolución de problemas, y evita tiempos de inactividad costosos en el futuro. Toda la industria se está moviendo hacia sistemas más inteligentes y reactivos, en los que cada componente contribuye a la eficiencia general de la planta.

Sección de Preguntas Frecuentes

¿Qué son las ventanas de inspección (sight glasses) y por qué son importantes en los sistemas de monitoreo?

Las ventanas de inspección son componentes que permiten a los operadores evaluar visualmente los niveles de fluido, su claridad y condiciones de flujo en tiempo real. Son cruciales para identificar rápidamente posibles fallos del sistema y prevenir averías en equipos.

¿Qué industrias utilizan comúnmente ventanas de inspección?

Industrias como la del petróleo y el gas, procesamiento químico y producción de alimentos dependen en gran medida de las ventanas de inspección para operaciones consistentes y para mantener estándares de seguridad.

¿Cómo contribuyen las ventanas de inspección a la reducción de costos?

Las ventanas de inspección ayudan a eliminar gastos por paradas no planificadas, reducen costos laborales mediante intervenciones específicas y optimizan el uso de recursos al detectar fugas y contaminantes.

¿Pueden las ventanas de inspección mejorar la vida útil del equipo?

Sí, al permitir un monitoreo regular y la detección temprana de posibles problemas, las ventanas de inspección pueden prolongar la vida útil del equipo al apoyar prácticas de mantenimiento proactivo.

¿Qué innovaciones futuras se esperan en la tecnología de ventanas de inspección?

Las innovaciones futuras podrían incluir tecnologías avanzadas de sensores que ofrezcan análisis mejorado para un monitoreo más preciso de los procesos industriales.

Tabla de Contenido

- Introducción - Importancia de las ventanas de inspección en los sistemas de monitorización

- Funcionamiento fundamental de las ventanas de inspección

- Industrias Críticas que Dependenden del Monitoreo Visual

- Identificación Visual de Anomalías e Irregularidades

- Estudios de Caso: Prevención de Fallas Catastróficas

- Integración con Sistemas de Mantenimiento Predictivo

- Eliminación de los costos por tiempos de inactividad no planificados

- Reducción de Costos Laborales mediante Intervenciones Dirigidas

- Optimización de Recursos mediante la Detección de Fugas/Contaminantes

- Simplificación de Ajustes en el Control de Procesos

- Garantía de Calidad mediante el Monitoreo Continuo

- Impacto en la Eficiencia General de los Equipos (OEE)

- Ampliar la vida útil del equipo mediante el cuidado proactivo

- Impactos de Sostenibilidad: Reducción de Recursos/Residuos

- Estrategias para Mejorar la Conformidad y la Seguridad

- Conclusión - Papel de los Visores en la Confiabilidad y el Mantenimiento del Sistema

- Innovaciones Futuras en Tecnología de Monitoreo Visual

-

Sección de Preguntas Frecuentes

- ¿Qué son las ventanas de inspección (sight glasses) y por qué son importantes en los sistemas de monitoreo?

- ¿Qué industrias utilizan comúnmente ventanas de inspección?

- ¿Cómo contribuyen las ventanas de inspección a la reducción de costos?

- ¿Pueden las ventanas de inspección mejorar la vida útil del equipo?

- ¿Qué innovaciones futuras se esperan en la tecnología de ventanas de inspección?